Logistics

As part of our full-service, vertically integrated model we have the ability to offer fulfillment and logistics services to our partners. Our experience allows us to handle orders/returns of all proportions depending on your company's needs, while managing the challenges of shipping and importing goods. We understand that getting your products to market efficiently is just as important as manufacturing them. Our logistics team works seamlessly with our manufacturing operations to ensure a smooth flow from production to delivery. Whether you need domestic distribution, international shipping, or complex fulfillment services, we have the infrastructure and expertise to handle it all.

Learn More→

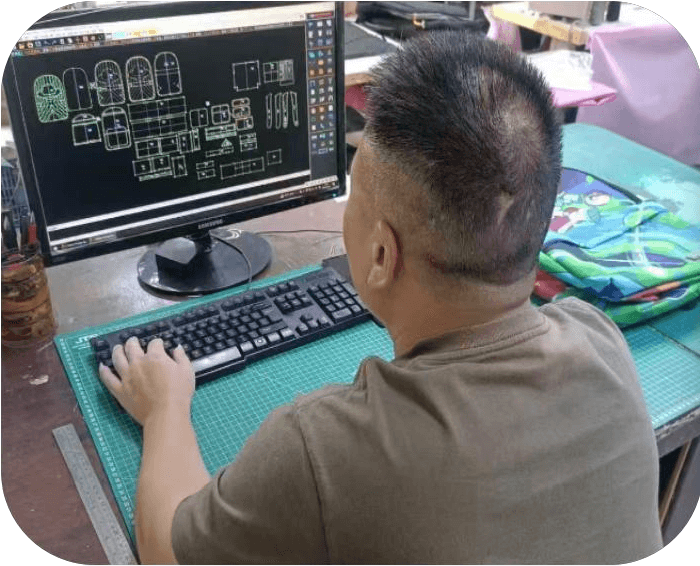

Design Services: Custom Luggage & Bag Creative Solutions

Our design service covers the full lifecycle of luggage and bag product development, starting with in-depth demand alignment: we communicate with brands to clarify core positioning, target audience, usage scenarios (e.g., travel, business, daily use) and functional priorities (e.g., load-bearing, waterproof, portability). Based on this, our design team integrates the latest industry trends—such as minimalist aesthetics, sustainable material applications, and smart functional embedding—to output 2-3 preliminary creative schemes, including style renderings, material matching suggestions, and structural design drafts. We then iterate the scheme with the brand: adjust details like pocket layout, handle ergonomics, and decorative elements according to feedback, and make sample-level effect predictions to ensure the design balances aesthetics and practicality. For IP co-branding needs (e.g., cooperation with Disney), we will also align the design style with IP image characteristics to enhance product differentiation. Finally, we output a complete design package including detailed drawings, process specifications, and material lists, which can directly connect to subsequent production links. Our service supports both new product innovation and existing product upgrading, helping brands quickly occupy the market with competitive luggage and bag products.

Learn More→

Source: One-Stop Luggage Material Procurement Services

Our procurement service provides one-stop material solutions for luggage and bag production, covering all categories: fabrics (durable Oxford cloth, waterproof nylon), leathers (genuine leather, eco-friendly PU), accessories (zips, buckles, handles, wheels) and auxiliary materials (threads, linings, padding). We have established long-term cooperative relationships with global high-quality suppliers, realizing stable sourcing of materials that meet international standards (such as environmental protection, wear resistance, and tear resistance). We support flexible procurement modes: bulk material supply for large-scale production, and small-batch customization for sample development. At the same time, our procurement team conducts multi-dimensional quality inspections on incoming materials—including material composition testing, physical performance verification (tensile strength, waterproof grade), and appearance defect screening—to ensure that each batch of materials meets production requirements. For brands with special material needs (e.g., recycled fabrics, flame-retardant materials), we can also coordinate with suppliers to develop exclusive materials, helping to enhance product uniqueness while controlling procurement costs and delivery cycles.

Learn More→

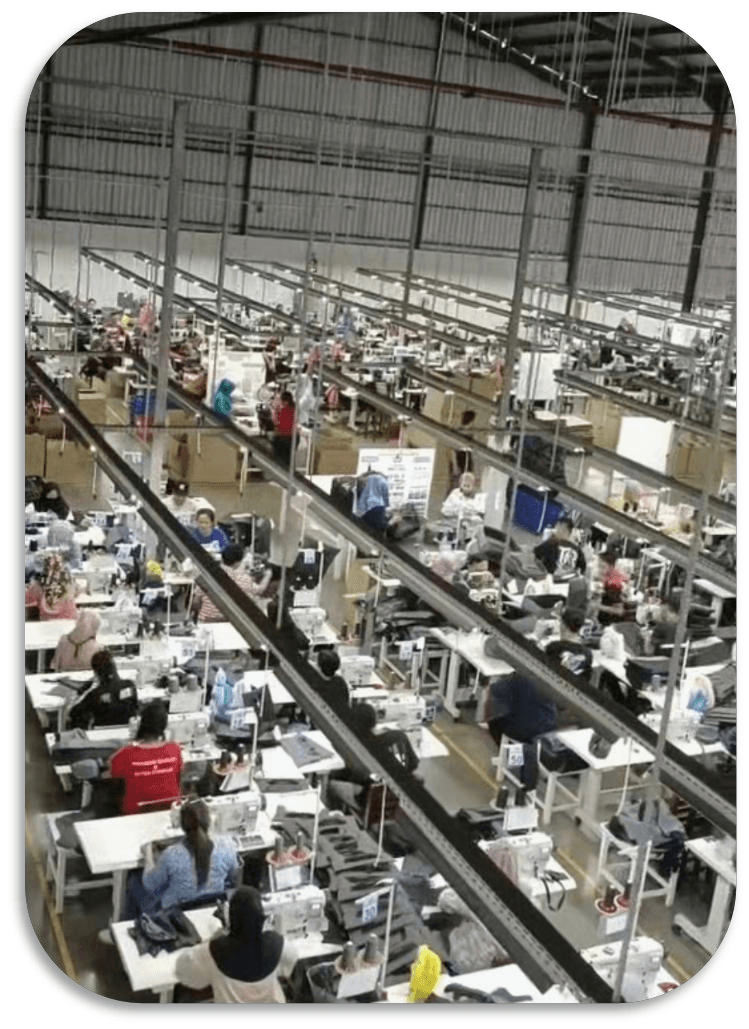

Contract Sewing

We provide professional contract sewing services tailored to textile product manufacturing: 1. Material Adaptability: Master stitching for fabrics (cotton, polyester), leathers (genuine/faux) and nylon (wear-resistant) with specialized needles and threads for each material. 2. Stitching Techniques: Offer 0.3mm fine stitching (for delicate parts), reinforced overlapping seams (for load-bearing areas) and decorative stitching (for aesthetic details) to meet functional and visual needs. 3. Custom Support: Accept small-batch orders (starting from 30 pieces), adjust stitching density/patterns per requirements, and align with brand sewing standards; free sample stitching is available for confirmation. 4. Quality & Efficiency: Conduct 8+ seam inspections (tension, neatness) to avoid fraying/thread breakage; our standardized production line ensures on-time delivery while maintaining consistent quality. We support partners in optimizing production processes and enhancing product durability through reliable sewing solutions.

Learn More→

Domestic Manufacturing

As one of China's large-scale and technologically advanced manufacturing enterprises, Chenfeng Luggage specializes in custom sewing services for industrial, commercial, fashion, and promotional products. We have established cutting and sewing production bases across the United States and around the world, boasting diversified manufacturing capabilities. Chenfeng Luggage leads the industry in both small-batch and large-scale production, as we are committed to helping micro and small entrepreneurs achieve faster scale expansion. Equipped with a full set of professional production equipment, the company relies on standardized production lines and a professional team to create a large number of job opportunities for the local economy, cultivate professional and technical talents, and effectively improve production efficiency. With superior product quality on a par with overseas counterparts, Chenfeng Luggage provides high-quality products to end customers of various cooperative brands, and fulfills the service expectations of brand partners with comprehensive services.

Learn More→

Overseas Manufacturing

We provide tailored overseas manufacturing solutions for bags and luggage: 1. Local Supply Chain Integration: Partner with regional material suppliers (e.g., European leather, Southeast Asian fabrics) to reduce logistics costs and shorten lead times. 2. Compliance Adaptation: Align with local industry standards (e.g., EU REACH, US CPSC) and labor regulations, ensuring products meet market access requirements. 3. Market Localization: Adjust designs (e.g., size, functional details) to fit regional usage habits (e.g., compact bags for Asian commutes, large-capacity luggage for European travel). 4. Quality & Coordination: Deploy on-site quality control teams, use standardized production processes, and support real-time communication (multilingual teams) to synchronize progress with clients. Our overseas manufacturing balances local adaptability and global quality standards, helping partners expand international markets efficiently.

Learn More→

Sustainable manfacturing

We offer sustainable manufacturing services for bags and luggage centered on environmental responsibility: 1. Eco-Material Adoption: Use recycled polyester (from plastic bottles), vegan leather (plant-based) and organic cotton—all certified by eco-standards (e.g., GRS) to reduce resource consumption. 2. Low-Carbon Processes: Optimize production lines to cut energy use (e.g., energy-efficient sewing machines), minimize water waste (closed-loop dyeing systems) and lower carbon emissions by 20% compared to traditional manufacturing. 3. Waste Reduction: Recycle cutting scraps (reprocess into small accessories), adopt precise pattern cutting (reduce material waste by 15%) and avoid single-use packaging for finished products. 4. Transparency & Certification: Provide material traceability reports, and support products to obtain eco-labels (e.g., EU Ecolabel) to meet global green market requirements. Our sustainable solutions balance environmental protection and product quality, helping partners build eco-friendly brand images.

Learn More→